-

Value - Added

Practices

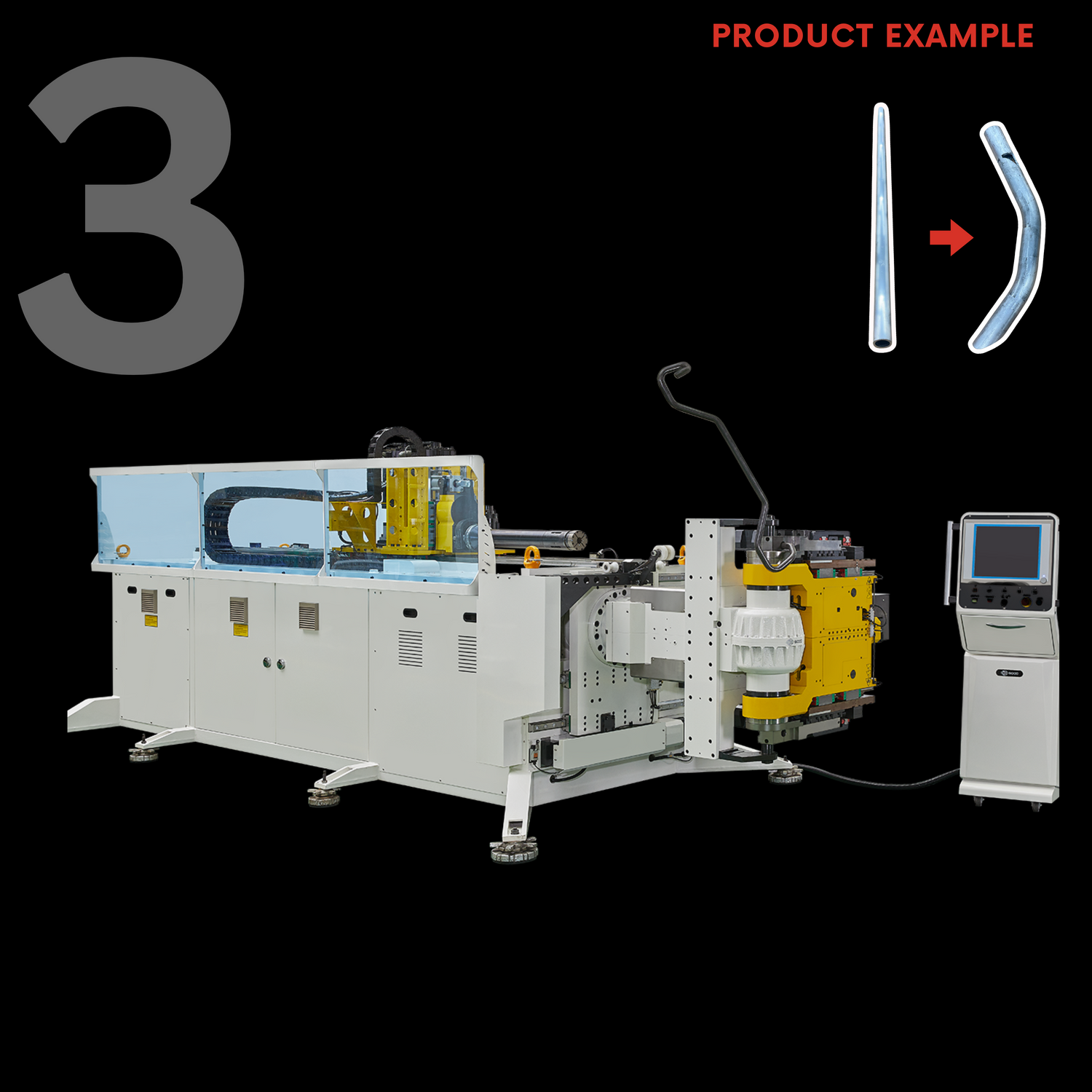

• Employing markers or tabs during laser cutting ensures seamless tube location for precise bending which results in high accuracy and efficiency. this translates into consistent, high quality results, meeting and exceeding industry standards

-

Customer

Benefits

• Our Team: Our team comprises an exceptional assembly of individual's-each one embodying an unparalleled level of skill, professionalism, innovation, and unwavering dedication.

• Cost-Efficiency: Leveraging our purchasing power, we provide premium materials at competitive prices, saving you valuable resources.

-

Customer

Benefits

• Speedy Delivery: With established supplier relationships, we ensure swift delivery times, keeping your projects on track.

• Uncompromising Quality: Count on Your MFG Supplier for precision, efficiency, and consistency in every tube produced.

Saw Cutting

Our advances band saws precisely tailor tubes to specific lengths, setting the stage for subsequent operations.

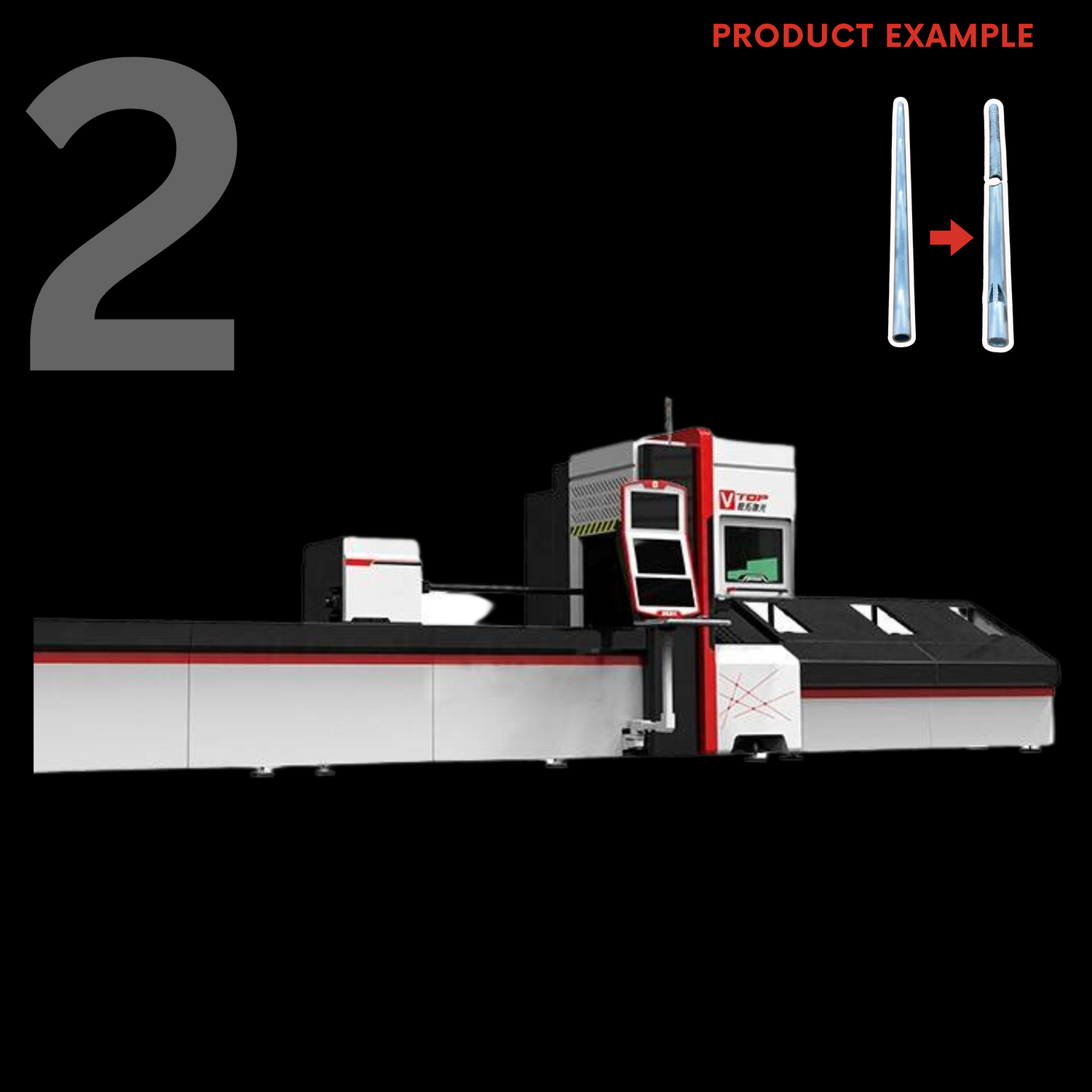

Fiber Tube Laser Cutting

Using fiber optic tube laser technology, We achieve unmatched precision in cutting tubes ranging from 3/4 - inch to 6 inches in diameter, Up to .120-inch wall thickness.

Expert CNC Tube Bending

our all-electric 10-axis cnc tube benders are equipped with:

• Mandrel and wiper dies

• Precision-driven electric machinery ensures consistent bend angles.

• In-stock tooling for rapid part development and/or production

Creaform Laser Scanning

Me measure all tubes during the setup process, Ensuring parts precisely match the model within specified tolerances.